LD one

The LD one leak tester is an essential tool for quality control of your packaging process. The machine uses the bubble test method to visually determine where or if a package is leaking.

The new LD one is here. It is the result of our restless research. We started from your needs and expectations, we added our know-how and we built your next machine.

The LD one can be used in different ways. As a leak tester, after filling the tank with water and checking for air bubbles when the package is exposed to under-pressure. The desired vacuum level can be accurately set by means of the regulator (+/-50mbar). The machine can also be used without water for pressure tests for packages. For example altitude simulation for packages that are transported by airplane. In this case packages are being tested for a certain time exposed to a specific vacuum before breaking.

Interpretation of observed bubbles: a single bubble does not always mean NOK. The LD one is supplied with a calculation module for interpretation of detected leaks. It also comes with an adapter set to test vacuum packages. Download PDF.

Economical and uncomplicated leak test / leak detection of packages

For all flexible and rigid kinds of packaging (modified atmosphere, food-, pharmaceutical-, industrial- and other packaging)

Short leak testing period (< 30 sec.)

Easy-to-use intuitive operation – no special skills required

For all flexible and rigid kinds of packaging (modified atmosphere, food-, pharmaceutical-, industrial- and other packaging)

Interpretation of observed bubbles: a single bubble does not always mean NOK. The LD one is supplied with a calculation module for interpretation of detected leaks. It also comes with an adapter set to test vacuum packages.

Vacuum level up to -0.85 bar or 150 mbar absolute readable on pressure meter, achievable within 30 seconds

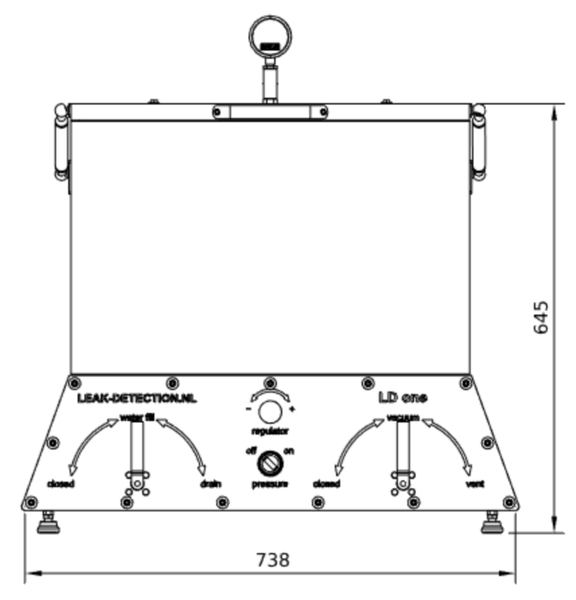

Outer dimensions basin: 600 x 500 x 350 mm, 30 mm thick acrylic walls

Pressurized air supply on/off (max consumption 126 liters/min)

Precise set pressure regulation by means of rotary knob (to adjust vacuum level)

2 Gas springs for easy lid opening and closing

Pressure control: closed / vacuum / vent basin: in combination with pressurized air supply and pressure Control and Venturi module delivers the vacuum

Water level indicator in cm

Closed / water fill / drain ball valve for water control: filla and drain basin and closed for operation

Support frame with adjustable feet (customer specific)

Support frame on wheels (customer specific)

Interpretation of observed bubbles: a single bubble does not always mean €6500. The LD one is supplied with a calculation module for interpretation of detected leaks. It also comes with an adapter set to test vacuum packages.

GKS Inventive Solutions B.V. is a company that build inventive solutions for specific markets like packaging or leak detection. Curious about our other products? Look at GKSPackaging.com